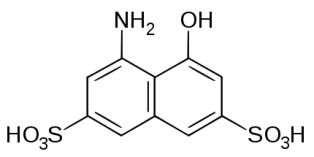

H-acid is one of the leading dye intermediates in the world, used in manufacture of black dyes. India is the second largest manufacturer of H-Acid in the world after China. However, H-acid is responsible for the most polluting industrial effluent in the dye and dye intermediate sector.

Did you know that manufacturing 1 kg of H-acid, results in the generation of 50 kg waste ?

In other words, it has an E-Factor of 50. In fact, the final isolation step is responsible for 50% of the overall waste generated. The waste is of dark color, strong acidity and contains substituted derivatives of naphthalene compounds. These organic substances are toxic, non-biodegradable, difficult to decolorize and resistant to conventional treatment. It has a very high COD of 1,50,000.

China and India – The hubs of H-acid manufacturing

Having considered the ill effects of H-acid manufacturing process, the developed countries of the world, with their strict environmental norms, gradually phased it out. Currently most of the developed world has banned it. However, the demand for H-acid continues – there is no other alternative on the horizon. For this reason, the manufacturing was outsourced to countries like China and India where environmental norms are not as strict.

The Bichhri Industrial Pollution Incident

The extent of the damage possible due to the generated waste is evident from the Bichhri industrial pollution incident. Bichhri, a small town near Udaipur was home to several H-acid plants. However, the toxic wastewater from the plants was left untreated and left to be absorbed into the earth, badly damaging the groundwater and soil, rendering it unfit for cultivation. H-acid plants in Jaitpur and Ratlam were also closed down for similar reasons.

What is the way ahead ?

In India, the bulk of the manufacturing happens in the states of Gujarat and Maharashtra by small and medium enterprises (SMEs) which are considered employment generators. Most of the H-acid is exported, bringing in valuable foreign exchange to our country. Considering these realities in mind, it is necessary to find a balance between environment protection and economic development. To achieve this objective, it is essential to incorporate the principles of green chemistry and green engineering in this process.