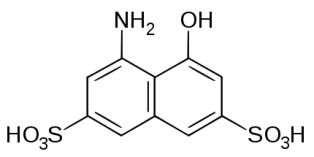

In our previous blog post, we talked about the H-acid effluent problem. Today we shall discuss one of the proven technologies to tackle it – Recycle@SourceTM solution.

Recycle@SourceTM Solution

Mumbai-based Newreka Green Synth Technologies Pvt. Ltd is a company involved in the development, customization and commercialization of green chemistry and engineering based solutions for pharmaceutical, dye and dye intermediate and fine and specialty chemical sectors. One such technology provided by Newreka is called Recycle@SourceTM solution.

The figure above shows the current industrial approach and the Recycle@SourceTM approach. A typical manufacturing process consists of several units. The current industrial practice is to collect the effluent from each unit and mix them together, so that the acidic and alkaline streams partially neutralize each other. This mixture is then sent for end of the pipe treatment like aerobic or anaerobic treatment, incineration, biological or biochemical treatment. In Recycle@SourceTM individual process steps are dealt with – the effluent stream is treated with customized proprietary performance additive R-Cat, which selectively removes organic and inorganic impurities so that the stream can be sent back to the same process step as reaction or extraction medium.

It enhances the yield as the valuable chemicals that were being lost in the effluent stream are now recycled back and the quality is consistent because R-Cat treatment does not allow the build-up of impurities. In this way, Recycle@SourceTM solution significantly minimizes the liquid effluent load and this reduces the cost of effluent treatment and disposal without compromising on the yield, productivity and quality.

Figure 2: Recycle@SourceTM applied to H-acid

Some numbers

Recycle@SourceTM

– provides minimum 10 recycles of the liquid stream

– effectively reduces the effluent by 90% per kg of H-acid

– brings a 10% increase in yield

In other words, Recycle@SourceTM helps in achieving the 3 Ps of Chemical Industry – Profit, Performance and Pollution Prevention. In case you are aware of more such solutions, please feel free to share!